DTF Transfer Sheets are crucial for direct-to-fabric printing, requiring a sheet with transparent film, adhesive, release layer, and backing. Selecting sheets involves considering fabric compatibility, print speed, ease of use, and cost. Design software like CorelDRAW, Adobe Illustrator, or Inkscape aids in creating intricate designs for DTF transfer films. Optimizing the process involves using specialized software, keeping designs clean, ensuring high resolution, and conducting test prints before mass production.

Discover the best software for swiftly creating high-quality DTF transfer sheets. In today’s digital printing landscape, efficient design is key. This article guides you through essential elements of DTF (Direct To Film) transfer sheets, highlighting top software options tailored for quick and precise design. Learn optimization tips to enhance your sheets’ performance and produce exceptional prints. Streamline your workflow with these recommended tools and techniques, ensuring accurate and vibrant results every time.

- Understanding DTF Transfer Sheets: Essential Elements

- Top Software Options for Efficient Design

- Quick Tips for Optimizing Your Transfer Sheets

Understanding DTF Transfer Sheets: Essential Elements

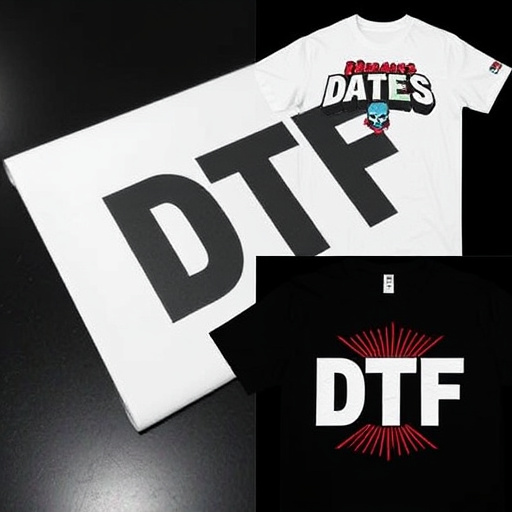

DTF Transfer Sheets are a crucial component in the printing process, especially for those utilizing direct-to-film (DTF) printers. These sheets serve as a medium to transfer designs onto various materials, particularly dark fabrics, with precision and ease. An ideal DTF transfer sheet should incorporate several essential elements: first, a high-quality, transparent film that allows for crisp image reproduction; second, an adhesive layer capable of securely adhering to both the print head and the fabric, ensuring accurate registration during printing; third, a release layer that facilitates easy removal after printing, without damaging the fabric or the design; and finally, a backing material that protects the transfer sheet during storage and handling.

Understanding the unique requirements of DTF printing for dark fabrics is paramount. The right transfer sheet must be compatible with a wide range of fabric types and colors, ensuring optimal results regardless of the final application. Additionally, factors like print speed, ease of use, and cost-effectiveness play significant roles in selecting the best software and hardware for designing and printing DTF transfer sheets quickly. Choosing a versatile solution that caters to these needs can streamline the production process, enabling users to achieve professional-quality outcomes with minimal effort.

Top Software Options for Efficient Design

When it comes to designing DTF Transfer Sheets for efficient and accurate bulk DFT shirt production, the right software is a designer’s best friend. Top options on the market streamline the process from start to finish, allowing creators to focus on their vision rather than technical hurdles. For clothing brands looking to incorporate logos DFT into their apparel line, these tools offer unparalleled precision and speed.

Whether you’re a seasoned graphic designer or just starting out, software like CorelDRAW, Adobe Illustrator, and Inkscape stand out for their user-friendly interfaces and robust features. They enable the creation of intricate designs with ease, ensuring that every detail translates perfectly onto the DTF transfer film. Each platform boasts its unique strengths—CorelDRAW offers powerful vector graphics capabilities, while Adobe Illustrator is renowned for its extensive design tools and seamless integration with other Creative Cloud apps. Inkscape, an open-source alternative, provides a wide array of features comparable to industry leaders at no cost.

Quick Tips for Optimizing Your Transfer Sheets

Designing DTF (Direct to Fabric) transfer sheets doesn’t have to be a complex or time-consuming task. Here are some quick tips to optimize your process and enhance your designs:

1. Choose the Right Software: Utilize software tailored for DTF transfer sheet creation, as it offers pre-set templates and tools optimized for fabric printing. This ensures accuracy and saves you from starting from scratch.

2. Simplify Your Design: Keep your designs clean and uncluttered to ensure smooth printing. Remove unnecessary details or consider downscaling intricate elements. For DTF printing on hoodies or t-shirts, simplicity often works best, allowing the design to stand out clearly.

3. Check Resolution and Color Profiling: Ensure your design is saved at a high resolution (300 DPI or more) for crisp prints. Proper color profiling ensures accurate color representation on various fabrics. This step is crucial when preparing DTF transfer sheets for professional use.

4. Test Before Mass Production: Always conduct test prints to check the quality and make adjustments as needed. This quick step saves time and resources, especially when producing custom designs for t-shirts or hoodies.

Designing efficient DTF Transfer Sheets can significantly streamline your production process. By understanding the essential elements and leveraging the right software, you can create optimized sheets that enhance accuracy and speed. The top-rated software options discussed in this article empower users to quickly design and edit DTF transfer sheets, ensuring a seamless workflow. Incorporating these tools and simple optimization tips will undoubtedly elevate your DTF Transfer Sheet creation experience, resulting in improved overall productivity.